|

CONVERTING YOUR 883

|

Quick Links:

|

Background Information

Converting your 883 to a 1250 or 1275 is absolutely the most cost-effective way to add power to your bike. Nothing else even comes close on a dollar

per horsepower basis. Converting your 883 is also a pretty

simple operation, you can perform a conversion in a few hours without even removing the engine from the frame.

Conversions can be done with no lower end work and they can be done using your stock heads and cams as well.

For these reasons, conversions are very popular, and we get asked about them practically every day. So we put together this

guide to help you understand the requirements and myriad of options associated with this very popular topic.

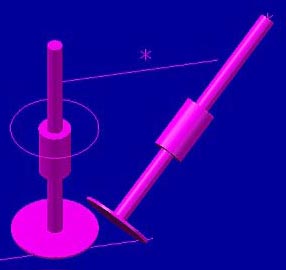

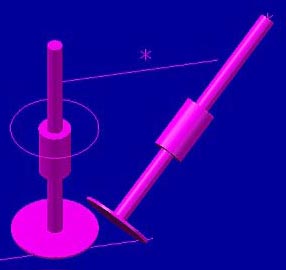

883 to 1250 Conversion Kit with Silver 04+ Big Fin Cylinders

Note the Reverse Dome Conversion Pistons

These Are For Use With Stock 883 Heads

Before we get into the nuts and bolts, though, there are some background things you need to know:

- One of the first decisions you'll want to make is whether to convert to a 1250 or 1275. HAMMER Performance provides a kit to do either. Here are some things to consider:

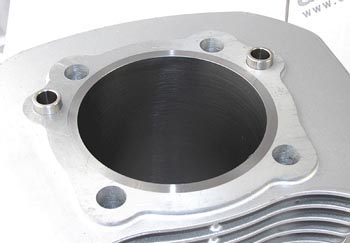

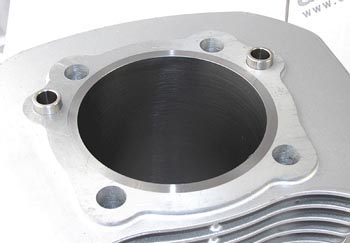

- The 1250 kit comes with new, premium quality cylinders with extra thick iron liners to support the larger bore size.

The 1250 kit is available with the basic conversion pistons only, for use with stock 883 heads. The higher power packages described below use the 1275 kit.

- The 1275 kit comes with new, premium quality cylinders with extra thick high strength steel liners to support the even larger bore size.

- Stock cylinders cannot be bored to the 1250 or 1275 bore size as the liners are just too thin.

- In addition to the engine kit itself, other parts are needed for a successful conversion. Which specific pieces are needed is a function of the year of your bike. See our

Complete and Matched Conversion Packages below

to make sure you get everything you need.

- XL cylinders from 1986 through 2003 use a small fin pattern, as opposed to the larger fin pattern found on 2004 and newer XL models:

Notice what a large difference this is. It adds considerable cooling capacity.

- Small fin cylinders (86-03) can be fitted to

2004 and newer models, however, be aware that they compromise the bike's intended cooling capacity, and also this swap has implications on the motor's appearance as the cylinder fins

won't properly match the fins on the heads. Also, the lower fin on the pushrod side will need some grinding to clear the pushrod tube bases.

- Big fin cylinders (04-up) will fit fine on 1986 to present bikes, and will add some cooling capacity to 86-03 models. However, consider the appearance issues if being

used under 1986-2003 small fin cylinder heads.

- The bottom line on cylinders is that if you have a 2004-up bike, we highly recommend staying with the large fin cylinders. If you have a 1986-2003 bike, we recommend getting cylinders

to match your heads, which in stock form means small fin style, however, many people upgrade their 91-03 heads with 04-up heads (see below), and in that case, we recommend getting the large fin style.

Both styles are readily available in

HAMMER PERFORMANCE 1250 and 1275 kits.

- In 2004, HD introduced oil squirters under the pistons to cool the underside of the piston domes. If pistons designed for 1986-2003 models are used in a 2004 or newer, you run the risk

of the piston skirts hitting the oil squirters, breaking them off and requiring a full tear-down to fix. All Sledge Hammer Pistons from HAMMER PERFORMANCE will clear the factory oil squirters just fine.

- With respect to interchangeability between cylinder heads, there are basically 4 generations to be aware of, with some interchangeability possible between them:

- 1986-1990 (4-speed heads): These heads have different valvetrain geometry than 1991 and newer heads, and therefore it is not recommended that you interchange 4 speed heads and 5 speed heads.

- 1991-2003: These are small fin heads with 5/16 stem valves and straight wound springs. The maximum valve lift they can safely support with stock hardware is .500". They can be interchanged with

2004-2006 heads except that a new front head mount bracket is required. A bracket designed to put a 2004 or newer head onto a 1991-2003 bike is readily available from HAMMER PERFORMANCE. No

bracket is currently available to fit this generation of head to a 2004 or newer bike, it would have to be fabricated.

- 2004-2006: These are large fin heads with 7mm stem valves and beehive springs. The maximum valve lift they can safely support with stock hardware is .560". These can be put on 1991-2003 models

with the use of a new front mount bracket. They cannot be used on 2007 or newer bikes without major modifications.

- 2007-present: These are large fin heads with 7mm stem valves and beehive springs and a .560" maximum valve lift as with the 2004-2006 heads. However, these heads are made for fuel injection.

The manifold surfaces are milled down .062" and the manifold flange bolt holes are also spread apart. These can be used on carb bikes with the addition of a special wider intake manifold

offered by HAMMER PERFORMANCE.

In summary, it's generally best to stay with the same generation of heads that your bike is made for. However, 2004-2006 heads can be fitted to 1991-2003 bikes without much trouble. You can read more

about the various details of XL cylinder heads in this tech article.

- 883 heads have shallower chambers than their 1200 counterparts, and longer valves to match. This makes the valves start out closer to each other and closer to the pistons.

As a result, in stock form 883 heads cannot accommodate as much overlap in the cams as 1200 heads. The critical dimension is the "TDC lift" spec of the cam grind. If we prepare the heads,

this changes of course, and we can put you into much more camshaft. Just keep in mind that you need to be very careful about cam selection when using 883 heads and understand

what will fit and what will have clearance issues. If in doubt, ask us.

- Since 1995, 883's and 1200's have shared the same crankshaft at any given model year. The crankshafts are balanced for a piston weight that's in between a stock

883 piston and a stock 1200 piston. The Sledge Hammer pistons from HAMMER PERFORMANCE that come in the 1250 and 1275 engine kits are in between the stock 883 and stock 1200 piston weights, so the

balance actually comes out better than either a stock 883 or stock 1200. So there is no need to be concerned with hurting the balance of the motor when doing a conversion with either of these kits, you'll

actually make it better.

- When converting an 883 to 1250 or 1275, it's always required to adjust both the spark advance and the fuel delivery.

See our engine kit installation instructions for details on how to do this.

Also read FAQ #5 and FAQ #6 below

- When considering what level of conversion to do from the descriptions below, keep in mind that stock heads require standard reverse dome conversion pistons, but a prepared head

works best with our trick 30 degree reverse dome pistons:

It's not that we can't prepare heads and continue to use the standard reverse dome conversion piston as shown on the left; we certainly can. However, it forces

compromises and ultimately ends up with a sub-optimal result. The higher up the food chain you go with the heads, the larger the compromise. This is because head work, particularly

large valve head work and/or head work done to complement high lift, high overlap cams, necessarily makes the chambers bigger. That puts downward pressure on the compression ratio,

while at the same time, larger cams generally require a

higher compression ratio, not lower. So the bottom line is that you need more piston dome as you move up the head prep and/or cam size

scale. We can only deck the heads to recover compression so far before we start causing a host of other problems, the right place to address it is in the piston dome. The

moral of the story is that pistons, cams and head work are a carefully matched set, and if you try to move up the power scale incrementally over time, you're likely

to either need to buy pistons twice (and they're expensive) or end up with a compromised result. See FAQ #2 below for more information.

- Through the 2003 model year, 883's and 1200's came with the exact same clutch setup. However, starting in 2004, the 883's got a lighter clutch spring. As a result, when you do a conversion

on a 2004+ 883,

it's necessary to upgrade this spring, either that or you can expect your clutch to slip. Many people take the opportunity to change the entire clutch pack at this time, swapping it for

an aftermarket "Extra Plate" clutch pack to remove the failure prone factory compensator plate. HAMMER PERFORMANCE offers upgraded springs, extra plate clutch packs, the compressor tool needed to

change the clutch spring, and the primary gasket you'll need. See FAQ #3 below for more information.

- Can you do the work yourself? The answer is an emphatic yes if you have the tools and a place to do it. Read our detailed and illustrated installation instructions here. And never forget,

we're only a phone call or email away if you have questions, that's what we're here for. We even answer emails evenings and weekends in most cases.

- Achieving optimum results requires proper assembly, heat cycles, break-in, and tuning. Don't cut corners on any of these things! Also read our tech article on How to Optimize Squish Clearance. This

little step will yield positive results in both power and fuel mileage.

|

Complete Conversion Packages

So how do you go about converting your bike, making sure you get all the right parts and services? Below, we've laid it out for you with a series of carefully matched, time-tested, proven packages, each of which

is designed to deliver a specific target power level in the most cost-effective way possible. Packages range from a low-cost 70+hp configuration up through

a 120+hp screamer. You'll find a description of

each package, dyno sheets, pictures, and even sample quotes you can download showing each item included and what it costs. Here are some other things to keep in mind:

- All of these packages are bolt-ons, and can be installed on a Saturday afternoon without even pulling the engine out of the frame.

- Although they're complete with everything you need and nothing you don't, the sample quotes below are just samples. We're more than happy to add or remove things at your request to meet your needs, just contact us.

- For the Basic Conversion Package,

you don't need to send us anything (except money!). It works fine with your stock heads, cams, etc. You can order this package directly below.

We normally turn this package around in 2-3 days. But these aren't normal times, Covid-19 has disrupted our supply chain. Turnaround right now is averaging about two weeks.

You'll get a ship notification email from the carrier when it goes out, so watch for that.

- All of the higher power packages require that you send us at least your cylinder heads, and in some cases your manifold and/or throttle body as well (although we may have cores available, contact us for details).

Please DO NOT send us parts until we have paperwork in place and we're expecting the parts! That just causes mass confusion.

So please, contact us first and we'll get a final estimate hammered out specific to your plans.

Once the plan is in place, follow

our shipping instructions.

Your project will be kicked off when your parts hit our door.

Turnaround varies with the season. It may be as short as two weeks in the slower months (August through October) or as long as 4-5 weeks in our busier months (February through May).

There's no need to worry about payment until your order is ready to ship, and we'll contact you at that time.

- All of the sample estimates below leave off both the exhaust and air cleaner. We do this because 99% of the guys who contact us already have aftermarket pieces for both, and in many cases, the parts

you already have will be suitable for meeting your goals. However, keep in mind that both your exhaust and air cleaner are critical performance components with the potential to make or break your

project. There are massive, massive performance differences from one aftermarket exhaust and/or air cleaner to another. The power of the motor tends to get defined by what holds it back, not by how

great the motor package is, and it only takes one part to hold it back. If your exhaust and/or air cleaner are not capable of supporting the target power level, you'll come up short!

We have enough experience that in most cases, we can advise you. One great resource is

our XL exhaust system dyno test library.

We can also provide air cleaners and exhausts that support your target power level.

- Except as noted, the dyno sheets below weregenerated with 1250 kits. Over time, we will be replacing these 1250

dyno sheets with 1275 versions as appropriate, but for now, just assume 2-3% more power over the entire rpm range for a 1275 as compared to a 1250.

- For the 80+ package and higher, we do not recommend ordering your engine kit separately from your head work. Reason being, during the course of the head work there's some precise

matching we do between the heads and the actual cylinders and pistons they're to be used with. If you've already taken delivery of your engine kit, we can't do this matching.

|

The Basic Conversion

The basic 883 to 1250 or 1275 conversion is a simple affair that makes a massive difference in the torque and power of the bike at a very modest price. Many, many people do a basic conversion only for this

very reason, in fact this is our number one selling package by a large margin. Here's what goes into a basic conversion:

- The stock 883 heads are reused as-is. If they have a lot of miles on them, you may consider a valve job and new valve guide seals.

- Either a 1250 kit or 1275 kit is used, and is configured with reverse dome conversion pistons to give 10:1 compression with the stock 883 heads.

You should stay at 10:1 or less when using stock cams and pump gas.

- Stock cams and valvetrain pieces are left in place.

- Upgrades to the air cleaner and exhaust are completely optional.

- If your bike is carbureted,

a new ignition module is a standard part of this package. 86-03 owners may opt out of the module and readjust their ignition timing to suit the conversion kit instead, but the motor will run sub-optimally

- Likewise, appropriate carb jets are a standard part of this package for 86-06 models.

- If your bike is injected,

a proper flash tuner is a standard part of this package.

- 2004+ models get a full upgrade to

an extra plate clutch kit including

spring compressor tool and

primary gasket.

That's it! With an afternoon of work, you've made a huge increase in the torque and power of your Sportster, and made it tremendously more fun to ride. How much more? Well,

here is an actual result we got:

Stock 2007 883 shown in green. In blue and red are the same bike after performing the basic conversion and adding a Patriot Defender exhaust and Air Hammer air cleaner.

This package will absolutely transform your bike!

And if you're a torque junkie ...

... these kits deliver it in buckets! The sheet gets

awfully cluttered if we add the stock 883 result here too, but it peaked at 49.3ft-lbs.

Sample Quotes and Pictures of the Basic Conversion Package

2014+ Basic Conversion Package (pdf): 1275 1250

07-13 Basic Conversion Package (pdf): 1275 1250

04-06 Basic Conversion Package (pdf): 1275 1250

98-03 Basic Conversion Package (pdf): 1275 1250

94-97 Basic Conversion Package (pdf): 1275 1250

91-93 Basic Conversion Package (pdf): 1275 1250

88-90 Basic Conversion Package (pdf): 1275 1250

86-87 Basic Conversion Package (pdf): 1275 1250

|

Click the Image Above for a

Slide Show of Packages for Different Model Years

|

Basic Conversion Package - 883 to 1275

|

|

Basic Conversion Package - 883 to 1250

|

|

Highlight Cylinder Fins - $50 per pair

Machined fin edges as found on certain 1200 models

Requires purchase of Basic Conversion Package

Note we do not offer a fin highlighting service for heads |

|

Looking to add or leave something out of the Basic Conversion Package?

You can order any or all of the pieces in the complete package at these links:

|

Taking it to 80+ Horsepower

So let's say you want a little more than the 70ish horsepower available from a basic conversion. What's the next step?

Well, the key to making more power is always to identify and address the thing holding the motor back. In the case of a conversion done with 883 heads, that's mostly the air flow capability

of the heads themselves. This airflow capability can be improved by working on the heads as well as holding the valves open longer with longer duration cams. To get to 80+ horsepower using an

883, we'll want to do both.

Here's what we'll do:

Here's what we'll do:

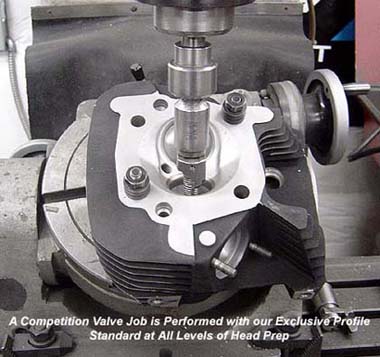

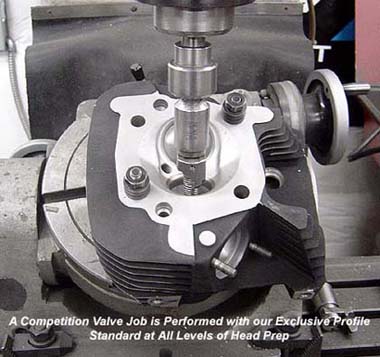

- The stock 883 heads will be treated to a Competition Valve Job.

This work goes right to the heart of the biggest problem with 883 heads, which is how the full size ports and bowls

neck down to the itty-bitty valves sitting on poorly blended seats. In stock form, it's a recipe for flow-killing turbulence. But the Competition Valve Job cleans this area up nicely.

The seat i.d.'s are opened up substantially, and the seats are blended into both the bowls and chambers. It makes a massive improvement to the flow of the heads.

- A 1275 kit equipped with our trick 30 degree reverse dome pistons is part of the plan at this level.We'll set this package up at 10.5:1 compression.

- A set of bolt-in style cams is used. For 86-03 models, the perfect match is the Andrews N4/V4 grind.

For 2004 or newer models, the IMPACT 560's are the best choice. Cams are required if

you want to run 10.5:1 compression on US pump gas. If you try to run 10.5:1 on your stock cams, detonation will be a problem and you may well damage your pistons.

Note however that we do have a 10:1 version of the 30

degree reverse dome piston if you plan to run stock cams or a high torque cam grind like our JACKHAMMER 570's

(the 570 cams are not compatible with 86-03 heads until you reach the 100+hp package head prep level, below).

- Upgrades to the air cleaner and exhaust are required to hit 80 horsepower. The best air cleaners on the market are the Air Hammer units from HAMMER PERFORMANCE - the

IMPACT model will do nicely for this package.

See our XL Exhaust System Dyno Test Library for more information on exhausts. We can provide most any exhaust that's on the market.

- At this level, a proper ignition module is required on all 86-06 models, as the increased compression and improved breathing demand a proper ignition curve. It's included as a standard part of the package, along with appropriate carb jets.

- Likewise, a proper flash tuner is included as a standard part of this package for all 2007+ (EFI) models

With this basic package, we've had many customers make mid

to even upper 80's torque and horsepower. It's a huge bang for the buck!

Here's an actual dyno result using this package on a 2004

XL883, EFI bikes with their stock "W" cams make even more:

You can see how well the motor responded to the head work and cams, as compared to the basic conversion, and there was no loss in bottom end power either. It's a great package for a very reasonable price.

Sample Quotes and Pictures of the 80+ Horsepower Conversion Package

|

Taking it to 90+ Horsepower

Okay, enough messing around, let's get serious about making some power!

The 90+hp Package Delivers a Huge Bang for the Buck!

Here's what we'll do:

Here's what we'll do:

- The stock 883 heads will be treated to an IMPACT porting job. This service includes the Competition Valve Job described in the 80+hp package above, but also

includes CNC reshaping of the ports themselves, which results in a substantial increase in flow.

- As with the 80+hp package, to get to this level you'll use a 1275 kit equipped with our trick 30 degree reverse dome pistons.

Again, we'll set this package up at 10.5:1 compression, but we do have a 10:1 piston available if you'd like to use milder cams and sacrifice some top end power for some additional bottom end power.

- As above, a set of bolt-in style cams is used: Andrews N4's if you've got an 86-03 model, and IMPACT 560's if your bike is a 2004 or newer.

- As above, upgrades to the air cleaner and exhaust are required.

- As above, ignition timing and fueling are adjusted with either an aftermarket ignition and some carb jets, or with an EFI tuner, depending on the year of your bike.

With this basic package, 90+ horsepower is well within reach and costs are still reasonable.

Sample Quotes and Pictures of the 90+ Horsepower Conversion Package

|

Taking it to 100+ Horsepower

Believe it or not, 100+ horsepower is available using your 883 heads, and at a very reasonable cost. HAMMER PERFORMANCE has a combination that can do it!

Yes, 100+hp is Possible Without Buying New Heads

Follow Our Formula to Get a Result Like This One

Here's how to get to the century mark and beyond at a very reasonable price:

- The stock 883 heads will be treated to a SMASH porting job. This service includes everything in the IMPACT porting

service described above for the 90+hp package, but also adds our oversized conversion valves and conical springs. We take your valve sizes up to the largest sizes

that will fit in the stock seats: 1.770" intake and 1.530" exhaust valves, in our stainless swirl polished high flow 7mm stem versions. We

pair these terrific valves with state-of-the-art conical springs and titanium retainers, a combination we've tested and proven stable to 8000rpm. Despite the tremendous rpm capability,

spring pressures remain mild to minimize wear and tear.

- A 1275 kit with 30 degree reverse dome pistons is again part of the plan, mirroring the 80+ and 90+ hp packages above.

Again, we'll set this package up at 10.5:1 compression

- To break 100hp, you're going to need a great set of cams, and the IMPACT 560's are exactly that. No worries if you have 86-03 heads as the SMASH service includes

an upgrade to the hardware and your heads will now support these high lift cams. IMPACT 560's are easy on the valvetrain and quiet in operation, too. You can expect a long,

trouble free life from this setup.

- Don't even think about doing this with a substandard air cleaner. Use a genuine Air Hammer air cleaner. The IMPACT model will support this level nicely.

- If you've got a carbureted bike, it's time to ditch the CV40 in favor of a Mikuni.

The preferred setup is an HSR45 and one of our HAMMER PERFORMANCE Billet Manifolds. These are included as a standard part of the package.

By going big like this, it allows us to do a better job on the ports, as we can maintain the proper taper from the carb to the choke point in the port. An HSR42 forces us to make a compromise here.

- The exhaust selection becomes critical at this level. The above chart was done with a Patriot Defender pipe, which is a superb performer at a bargain price.

See our library of XL Exhaust System Dyno Test Results for other candidate pipes.

- An appropriate ignition module and is included as a standard part of the package for 86-06 (carbureted) bikes.

- The best EFI tuner on the market is included as a standard part of the package for 2007+ (EFI) bikes.

Sample Quotes and Pictures of the 100+ Horsepower Conversion Package

|

Taking it to 110+ Horsepower(applicable to 2004+ XL1200's as well)

Actual Result From our 2007 XL883 Sportster With the 110+ Horsepower Package

Who says you need 1200 heads to make big power? Not at HAMMER PERFORMANCE! We've made over 120 horsepower on 883 heads

with this package. You should have no problem breaking

110hp; truth be told even 115 is an easy mark for this combination.

Here's how to get past the 110hp mark with your 883:

- Hit it as hard as you can, use a SLEDGE HAMMER! Once you get to the SLEDGE level, 883 heads no longer give up anything to equivalently prepared XB or late model XL1200 heads.

Four new seats and the largest valves we can make fit are just the beginning. We complement these valves with extensive chamber work and

our exclusive SLEDGE custom tailored porting process.

A set of state-of-the-art conical springs with Ti retainers gives you a valvetrain safe to 8000rpm, but because of the lightweight components and the advanced

lobe design of the cams below, it's done without the high spring pressures that increase wear and tear.

When it's all said and done, your 883 heads will perform every bit as good as the best prepared XB heads, but without the big expense!

- It not only takes big valves to flow enough air to make 110hp, it also takes bigger cams. Our CRUSH 600 cams are proven power

producers. But the lobe design is both quiet and easy on the valvetrain, and the gentle ramp rates don't need the brutal spring pressures required with other cams in this size range.

Truly a real-world set of cams with longevity and reliability, and perfectly matched to our head work and engine kits, these are the ideal choice.

- Your 1275 kit will get a special set of 30 degree pistons, designed to push the compression a bit. Don't worry though, the later intake close timing

of the CRUSH 600 cams bleeds much of this off. Expect 200-210psi of cranking compression when it's all said and done, which is fine with proper tuning.

- To deliver all the air this monster needs, you'll need the best air cleaner made, and that means the CRUSH model Air Hammer.

- If you've got a carbureted bike, the package includes an HSR45 Mikuni and a HAMMER PERFORMANCE Billet Manifold.

If your bike is injected, you have a 45mm throttle body already, but the throttle body and manifold both benefit greatly from a little work.

Send it to us along with your heads for porting.

- You're going to need the best exhaust on the market, and the best we've ever tested is

the Patriot Defender.

Set the baffle butterfly wide open and leave it there.

See

our exhaust system dyno test library for lots of

information on XL exhaust system performance.

- As with the other packages described above, this package includes an appropriate ignition module (carbureted bikes) or EFI tuner (injected bikes).

Assemble it correctly, optimizing your squish clearance along the way. Heat cycle and break it in correctly and then get it on the dyno for a thorough tune-up. 110 is an easy mark, and over 115 is well within range.

And just in case you're still worried you're somewhow giving up some power by sticking with your 883 heads, check out this sheet:

In blue is a set of SLEDGE PLUS ported EFI 1200 heads with an HPI 55mm throttle body

In red is a set of SLEDGE ported EFI 1200 heads with a ported factory throttle body

In green is a set of SLEDGE ported EFI 883 heads with that same ported factory throttle body

SLEDGE PLUS service adds welding up of the port so that we can make an optimum shape

Collectively, the PLUS service and the HPI throttle body added only 3hp

Sample Quotes and Pictures of the 110+ Horsepower Conversion Package

|

Taking it to 120+ Horsepower(applicable to 2004+ XL1200's as well)

Actual Result From our 2007 XL883/1275 Sportster With the 120+ Horsepower Package

HAMMER PERFORMANCE raises the bar again! This package achieves levels of bolt-on performance never before seen in the industry! And we've done it in a reliable,

pump gas friendly combination. The above motor has only 200psi of cranking compression and only moderate valve spring pressures. These results are achieved

with modern technology and innovation, not

excessively high compression and brutal cams!

Here's what goes into the 120+ package:

- To get to this level, we had to invent a whole new head prep service. The BFH Head Porting Service has some major improvements over the SLEDGE service:

- We do a limited amount of welding on the floor of the ports, to add some material where they desperately need it. This allows us to make an even better port than is possible with our

SLEDGE porting service. The floors are really the only place in the port that welding can be done without creating risk of other problems.

- We alter the valve angles, spreading the valves farther apart.

|

The valve placement and angles were 3D modeled to determine the ideal angles for the valve sizes and cam overlap.

Once the final design was determined, toolpaths were derived for the CNC machining operations.

|

The larger valves and higher rpm potential called for the latest in valve spring technology. Beyond a beehive, these recently introduced high tech springs provide natural damping of

oscillations via a different resonant frequency for each coil. Spring pressure is increased only slightly, to maintain a durable, long life valvetrain. The valvetrain is rock solid

stable to at least 8000rpm with this combination.

|

The valve tip remains in the same location so that no changes to the rocker arms are needed. This allows us to use larger

diameter valves.

7mm stems are retained, to provide a lightweight valvetrain that does not require brutal spring pressures to maintain high rpm valve control. Special cone shaped single wound springs

that provide natural damping of harmonic resonances are used to provide superb control of the larger valves with only a nominal increase in pressure. These springs are state of the art

and only recently developed.

- We invented the world's first bolt-on 1275 kit! The 1275 kit was invented specifically for this package, and then later filtered down to the other packages described above.

The HAMMER PERFORMANCE Bolt-On 1275 Kit

No Case boring Required!

To accommodate the larger, more spread apart valves as

described above, we increased the bore size on our world famous 1250 kits. This is made possible by a special

120,000psi tensile strength steel liner, which allows the cylinder spigots to be made thinner. NO CASE BORING IS REQUIRED, this continues to be a bolt-on kit just like the 1250. This new steel liner

also does not compromise liner thickness in the working area of the cylinder. The extra strong material makes it even more structurally stable than our legendary 1250 cylinder!

|

The 120,000psi Tensile Strength Steel Liner Enables a Thin Spigot for a Bigger Bore

|

The Working Area of the Liner Remains Thick to Promote a Straight, Round Bore that Doesn't Distort Under the Heat and Pressure of a Running Engine. This Results in Superb Ring Seal.

|

- This power level starts to outrun the factory 45mm EFI throttle plate, as well as the HSR45 Mikuni on carb'ed bikes. So the EFI version of this package includes an HPI 51mm throttle body,

and we port it's manifold as well. The carbureted version uses

an HSR48 Mikuni mounted on one of

our billet intake manifolds.

- To complement the extra large valves,

1.725 ratio rocker arms are a standard part of this kit. Large valves bring in most of their flow gains at higher lifts, and the high ratio rockers allow

us to achieve this higher lift without creating cam box clearance issues or problems with the factory lifter anti-rotation device.

- As with the 110+ package, you're going to need the best exhaust on the market, and the best we've ever tested is

the Patriot Defender.

Set the baffle butterfly wide open and leave it there.

See

our exhaust system dyno test library for lots of

information on XL exhaust system performance.

Sample Quotes and Pictures of the 120+ Horsepower Conversion Package

|

Frequently Asked Questions

-

Can't I do a conversion with a set of cams but no head work?

- The short answer is yes, but you need to keep it mild.

Reason being, stock 883 heads kind of put you in a box with respect to cam selection.

On the flow bench, they nose-over before they even get to .400" of valve lift.

In other words, lifting the valves beyond .400" doesn't cause the flow to increase any more.

So even the stock cams are lifting the valves more than does any good, and there's no gain to be had by lifting more.

Furthermore, 883 heads have shallow chambers and long valves to reach them.

This puts the valves much closer to the pistons to begin with, and really compromises piston to valve clearance.

Cams with high overlap, as reflected "TDC Lift" specs higher than about .200" on either valve, run the risk of causing piston to valve contact.

So there's limited opportunity to increase overlap, which is a key, key way to make more power with a cam swap.

You can choose cams with a later intake close point to get more power, but that tends to just rob from the bottom and middle to give to the top end.

Bottom line, you're in a box and there are no cam miracles when using stock 883 heads.

They can't take much cam and therefore the benefit is limited.

All that changes of course when you prepare the heads.

See the 80+hp through 120+hp packages described above, those are all about careful matching of head work to cams, and to the pistons for that matter. Everything needs to be a matched set.

If you have stock 883 heads and you're considering a cam swap, here's some hard data chew on:

- Andrews N2's are shown in blue. These cams are safe for use with stock 883 heads.

- "W" cams are shown in red. These cams are factory original equipment in 2007+ XL883's. They have the earliest intake close timing of any XL cams available, which is why they're so

strong on the very bottom of the chart. These can be retrofitted to 1991-2006 models, and a used set can often be found cheap on Ebay or the like. Just be careful to get a compatible set.

1991-2003 models need a set that's machined for the timing cup as shown on the left in this picture - nearly as we can tell they stopped machining

them for the timing cup sometime during the 2006 model year, but always verify.

Also pay attention to the pinion gear tooth pitch. To put 00+ cams into a 91-99 or vice-versa, you can either

swap your pinion gear or move your old #2 cam drive gear to your new cams with a press.

- "D" cams are shown in green. These cams are factory original equipment in 1991-2006 XL883's.

These three grinds are literally the three mildest cam options you have.

After seeing this chart, many people with "D" cams opt for a set of "W" cams, and many people who already have "W" cams choose to just leave them in place.

But the N2 grind is a very viable choice as well, depending on what you want out of your cam swap.

And if you don't mind giving up some bottom end in favor of more top end, the Feuling 505/515 grind is safe for use with 883 heads and has timing designed for top end power.

Many customers ask us about the Andrews N4 cams as well.

N4's have a .216 intake TDC lift, which can get you in trouble when using stock 883 heads.

In our experience, N4's cause piston-to-valve contact about half the time, when used with stock 883 heads.

If you want the type of power band delivered by the N4's, we suggest the Feuling 505/515 grind.

The very low .137/.150 TDC lifts make them perfectly safe for use with stock 883 heads.

Here are the pieces you should consider if you're swapping cams and using stock 883 heads:

- The Andrews N2 or Feuling 505/515 cams

- A cam box gasket and a rocker box gasket set

- Assembly lube - you'll want to slather up the cams good on assembly.

- A suitable tuner (EFI models) or jets (carbureted models) - Swapping the cams is going to change the airflow through the motor, and as a result,

you need to adjust the fuel delivery to match. Although EFI bikes may get by with a simple piggy back style tuner, if an engine kit is in your future then you should probably bite the bullet

and get a good flash tuner capable of supporting the kit. A Dynojet Power Vision PV1B (2007-2013) or PV2B (2014-2022) is what we offer and recommend and support for use with our 1250 and 1275 kits.

- A bronze oil pump drive gear and pinion locking tool - These are not strictly required, but it's something you should consider.

As you raise the power level in a Sportster, the stock steel gear becomes a high failure item, and it's an ugly failure, causing a loss of oil pressure and shrapnel through the motor and generally requiring a full tear-down to fix it.

This was a terrible problem on even bone stock Buells because they were coming from the factory with 85-90hp. HD finally came out with this bronze gear in 2006 and put it in all the Buells starting that year.

But they never put it in Sportsters because it's more expensive than the steel gear and failures in stock Sportsters were almost unheard of.

When you're swapping cams, you're right there anyway, so this is a bit of insurance you should consider.

The pinion locking tool is essential for installation, because holding the crank still by any other method puts it at risk of scissoring when you loosen and tighten the pinion nut.

Note that if you get one of the complete packages offered above, it comes with the rocker box gaskets (part of the top end gasket set) and the tuner (EFI bikes) or jets (carbureted bikes).

-

I'd like to do a basic conversion now, but work toward a higher power conversion over time, to spread out the cost. How can I do that?

- Unfortunately, there's no good way to do this. The bottom line is that these power packages

are very carefully matched with respect to the heads, cams, and pistons. They work together, not only for power production but also just to have enough physical

clearance for everything to fit and work, as well as deliver an appropriate compression ratio. Just as an example, the IMPACT 560 cams will only work with 883 heads if

the valves have been recessed in the seats significantly, both to correct the valvetrain geometry for the high lift and to gain the valve to valve and valve to piston

clearance needed. This, and the unshrouding work that goes with it, makes the chambers bigger, requiring more piston dome to compensate. But that's just one example,

there are several more. The bottom line is that if you try to do the project incrementally over time, either you'll need to buy some parts (like pistons) twice, or you'll

severely compromise the end result. Not the answer we want to give, but we can't change the laws of physics.

-

What are my options on the clutch?

- 883 Models since 2004 have been coming from HD with a weak clutch spring. When you do a conversion on a 2004 or newer model, at a minimum you need to change the spring.

A spring is inexpensive, however, to change it requires

a spring compressor tool and you'll also probably want

a new primary gasket, we offer a high quality rubber coated steel

gasket.

- Embedded into the middle of the factory clutch pack is a compensator plate that's held together by brass rivets. Failures of these assemblies aren't nearly as rare as they should

be, in fact the compensator plate has been nicknamed the "grenade plate" in some circles. For this reason, many people will go ahead and change it out for an aftermarket "extra plate"

clutch pack, especially if they're in there anyway to upgrade the spring as a part of a conversion. The extra friction disc and steel plate included in the extra plate kit together

eliminates the factory grenade plate. It's a simple piece of preventive maintenance you can perform. We like and offer

the Energy One extra plate clutch pack, which comes with the spring you need

-

What other things should I do to hold the extra power without compromising reliability?

- Sportster models (except the XR1200) have an oil pump that's driven of the pinion shaft by a pair of gears. At higher power levels, the cranks tend to develop slightly more

runout due to flywheel spread, and it causes the oil pump drive gear on the pinion shaft to wear badly on one side. You'll see the teeth getting sharp in one area, and 180 degrees

from that spot they'll look like new. Eventually the teeth fail and it's ugly.

This was an especially bad problem on stock Buells due to their higher power level, and in 2006 HD finally came out with a solution, a bronze drive gear. But they never put this

gear onto Sportsters, it just wasn't a bad enough problem at 65hp. When you're hopping up an XL, it's a good idea to swap out your stock gear in favor of this bronze unit.

HAMMER PERFORMANCE

offers the gear as well as

the special pinion locking tool you need to change it properly. It's cheap insurance against a catastrophic failure, especially if you're in the cam

box anyway as a part of a hop-up project.

- The stock primary chain tensioners on

1991-2000 models are failure prone at higher

power levels. We highly recommend that you

upgrade

this tensioner with a heavy duty replacement..

- Similar to the primary chain tensioner issue, on 1991-2001 models the alternator hat was held to the front primary sprocket with 4 bolts, and at higher power levels, these

like to shear off. We highly recommend that you

upgrade to an 8-bolt sealed magnet

rotor that will not shear off and also protects the very fragile rotor hat magnets from damage.

-

Is a new ignition module really necessary?

- When you convert an 883 to a 1250 or 1275, the speed of the burn goes up dramatically for a couple of reasons. For one, the engine kit almost always brings with it an increase

in compression from the 883's stock 9:1. But in addition to that, a conversion generally adds

a squish band to the chamber, which increases chamber turbulence, also increasing the

speed of the burn.

- This faster burn requires you to reduce the ignition advance. If you don't pull the timing back (see

our installation instructions for specifics), you'll lose power, the

engine will run hot, and it's highly likely you'll damage the pistons via detonation or scuffing.

- If your bike is a 2007 or newer, the ignition is controlled by the ECM and the timing tables in the ECM need to be modified accordingly, using a good flash tuner like

the Power Vision PV1B or PV2B.

We will provide the map, see

the kit

installation instructions for details.

- If your bike is a 2004-2006 model, you have no mechanical timing adjustments. The only way to adjust your ignition timing for the conversion is to replace the module

itself with a unit that provides adjustability.

We prefer the Daytona Twin Tec TC88A.

- If your bike is an 86-03 model,

a new ignition module is highly suggested but not strictly necessary. These years have a mechanical adjustment that allows you to reduce

overall timing advance which will keep the pistons from being damaged. However, this is less than ideal for a couple of reasons:

- The faster burn of the engine kit really wants a much softer curve, i.e. the timing should be brought in more slowly. So in the ideal world, your idle timing

should be close to stock, but the advance slope should be softer, reaching it's maximum advance of about 28-30 degrees at 4500-5000 rpm. The curve that's programmed into

a stock 883 ignition module is much more aggressive than this. Retarding the timing via the mechanical adjustment moves the entire timing curve down but does nothing to

change the shape of the timing curve. Bottom line, adjusting the timing instead of replacing the module will leave significant power on the table, because when you take out

enough timing to make the engine kit safe, much of the curve will softer than optimum. In particular, you may have trouble with low speed operation, i.e. idling and

pulling away from a dead stop under heavy load.

- Adjusting the module does nothing to raise your rpm limit, which becomes especially important in a performance type build

- Bottom line, if you have an 86-03, and you're just doing a basic conversion, and you're real tight on funds, you can get away with just retarding your timing per the instructions,

although it's certainly not optimal. If you're converting an 04-06, or if you're doing any kind of a performance build on any

86-03, you need the ignition module. If you've got an

07 or newer, let us help you with a new ignition map for your ECM than you can install using a flash tuner.

-

What tuner devices will work with a 1250 or 1275 kit??

- Get a flash tuner. Flash tuners work by actually reprogramming the various settings and tables within the factory ECM, to teach it about the new engine configuration. This is the

right way to do it.

- Among flash tuners,

the Dynojet Power Vision (PV1B/PV2B) really stands out for it's ease of use and tremendous capabilities. For that reason, this is the device we've chosen to primarily

support for use with our engine kits. If you use a Power Vision PV1/2/3, we will provide you with a starting point map, which in many cases will be very close to what you need, as we've developed

maps for a large number of combinations. You can then dial it in from there to your specific bike using the Power Vision's built-in autotune capabilities. We've had hundreds of customers

successfully tune their bikes using this method.

- Customers have also had success using flash tuner products from TTS, Screamin Eagle, DirectLink, ECM Spy, and the V&H FuelPak 3 device (NOT the FP1 or FP2). For any of these

devices, we will give instructions and certain table values and settings for setting up the initial tune. You will most likely be typing the values in manually. You will then use the logging & tuning process associated

with that tuner to dial in your VE tables (Vtune for the TTS, SmartTune for the SEPST, etc).

- Special note about the FP3:

- This device is gaining in popularity due to it's relatively low price and the popularity of V&H exhausts. However, customers are getting mixed results when

trying to apply it to the 1250 & 1275 kits. Because the FP3 operates in a closed ecosystem, with no capability to receive or send tunes to anyone except V&H, tune values have to be typed

into your phone manually. Well, punching the table values and settings we provide into a smart phone is time consuming, tedious, and error prone. We've had customers do it

and use the autotune capability and achieve a satisfactory tune. We've had others get frustrated with the process and/or fail to achieve a satisfactory tune, and end up throwing in the towel

and upgrading to a Power Vision PV1/2/3. We get far, far more requests for help in getting bikes to run right from FP3 users than from Power Vision PV1/2/3 users, too. It costs us a lot of time in support.

- Worse, we've had a disproportionate number of customers damage their engine kits when trying to tune with an FP3. Just to put some numbers to it, of the first

200 1275 kits we sold, five customers scuffed their pistons. Four out of the five were FP3 users, despite the fact that FP3 users represent only about 25% of our customer base. How much of that

was errors punching in the table values and settings, we don't know because there's no way for them to send us the tune so we can examine it. At least one of those customers sent our tune specs

off to V&H and had them build the tune for them.

- So our general advice is this. If you don't have a tuner yet, and you're considering a 1250 or 1275 kit, avoid the FP3. Follow our recommendation and get a Power Vision (PV1B or PV2B depending on the year of your bike), life will

be much easier and there will be less risk and it's really a much more capable device. Likewise, if you're going for one of the high power packages, avoid the FP3 and get a Power Vision PV1B/PV2B. The quality

of the tune becomes increasingly more important as you move farther up the power chain and the FP3

becomes less and less suitable. But if you already have the FP3, and you're getting a Basic

Conversion, you're free to try to make it work and we'll do our best to help you be successful with it. Just be be sure to get your tune values from us and type them in carefully and accurately

and follow our instructions. Do not get your tune from V&H or have them build your tune from our specs.

- We do not support any piggy-back type tuner devices (Power Commanders, Cobra, FuelPak 1 or 2, Patriot Top Fueler, etc). Piggy back tuners work by hanging off the outside of the factory

ECM, intercepting and modifying signals coming and going to "fool" the ECM. The ECM doesn't even know it's there, as far as it's concerned it's operating a stock motor.

This approach is fine for pipes and air cleaners, but it starts to break down when you go making 40% changes

in displacement, which is what the 1250 & 1275 kit does. Many of them are simply not capable of providing the additional fuel required of a 40% change in displacement, and also many of them

will not alter the ignition timing appropriately to compensate for the faster burn of the 1250/1275 kit, which will damage the pistons quickly. But even

the piggy-backs that provide adequate fueling and timing control typically don't work well with a conversion. The reason is that there are numerous fine trim adjustments made to the fueling

by the ECM to deal with various special conditions, and these fueling adjustments should not be amplified by the displacement difference the way the mainstream fueling is. The result

is generally unsatisfactory low speed manners, and general running problems. You're welcome to try a piggy back tuner on your engine kit, but we've had

several customers do so,

fail to achieve a satisfactory result (or worse, damage their engine kit), and give up and go get a good flash tuner.

We don't think it's worth your trouble to even

mess with it.

-

What's the best package I can get that will still be reliable and last a long time?

- None of the packages themselves will compromise reliability or longevity at all. Although there are certain items that become failure prone at higher power levels, good fixes for these

things exist and they are included in the packages as appropriate.

- How you ride the bike however will most certainly affect reliability and/or longevity. In particular, if you spend a lot of time at high rpm, your risk of a part failure goes up as does

the rate of wear. But if you ride the bike the same as before the motor package, with only occasional visits to the upper rpm range, reliability and longevity are not affected.

This statement is true for all of the packages.

-

What will the engine package do to my fuel mileage?

- Although we don't like to advertise this, generally speaking the addition of one of our performance kits creates a small improvement in fuel efficiency, when the bike is ridden normally.

Although the motor is capable of much more power after installing the package, you are in control of the power with your right wrist. The bike does not require any more power to

go down the road at a given speed than before, so you wind up giving it less throttle to go the same speed. Bottom line, the package generally makes the motor more efficient at turning fuel into

power (assuming the motor is tuned properly).

- That said, there is a condition under which fuel mileage could suffer. If your exhaust creates a "reversion" in the rpm range in which you ride, this reversion is likely to become more

of an issue after the package is installed, if the package includes high overlap cams (which all of them do except the basic conversion). Overlap is enormously important for making power, but

it relies on an exhaust that's on the same page, and when the exhaust isn't working well, overlap gives it more opportunity to hurt cylinder fill and thus torque and power. Short, open pipes

are especially prone to this condition (LAF pipes, drag pipes, etc). If you have this condition, we suggest baffling or replacing the pipes.

- Generally speaking, a properly tuned Sportster with a solo rider and typical load should average between 45 and 50mpg in normal riding. If it does significantly better than this, it's

probably too lean, and if it does significantly worse than this, it's probably too rich.

-

Should I change my 883's gearing when I do a conversion? What are my options?

- The vast majority of conversions are done without a change to the gearing. It's completely optional.

- The advantage of the shorter 883 gearing is quicker acceleration.

- The advantage of the taller 1200 gearing is reduced engine rpm at highway speeds.

- If you have a 1991-2003 model:

- 91-03 XL883 and XL1200 models share the same primary gearing: 35T front sprocket and 56T clutch basket.

- However, the final drive differs. Belt drive 883 models came with a 27T front sprocket and 1200's came with a 29T front sprocket. Both models came with a 61T rear sprocket.

- Changing your 883 to the 29T front final drive sprocket will result in a 7% reduction in rpm at any given speed.

So for example, if you're turning 3000rpm now, at that same speed you'll be turning about 2800rpm after changing to the 29T sprocket

- If you have a 2004+ model:

- 2004+ XL883 models have a 34T front primary sprocket and 2004+ XL1200 models have a 38T front primary sprocket. Both models have a 57T clutch basket.

- XL883 models from 2004-2010 came from HD with a 28T front final drive sprocket, and 2011+ came with a 29T front final drive sprocket.

- 2004+ XL1200 models came from HD with a 29T front final drive sprocket.

- HD also offered a 30T front final drive sprocket on certain international models.

- All 2004+ models, 883 and 1200, came from HD with a 68T rear final drive sprocket.

- Here are all the possible gearing combinations with factory sprockets, in order of shortest to tallest:

- (57/34) x (68/28) = 4.07 overall in top gear (stock 2004-2010 XL883)

- (57/34) x (68/29) = 3.93 overall in top gear (stock 2011+ XL883)

- (57/34) x (68/30) = 3.80 overall in top gear (XL883 primary with HDI final)

- (57/38) x (68/28) = 3.64 overall in top gear (XL1200 primary with 2004-2010 XL883 final)

- (57/38) x (68/29) = 3.51 overall in top gear (stock 2004+ XL1200)

- (57/38) x (68/30) = 3.40 overall in top gear (Stock 2004+ 1200 primary with HDI final)

- From the shortest combination above, to the tallest, you would reduce your rpm at any given speed by about 16%, which is a LOT.

For example, if you're turning 3000rpm now with the shortest combination, you'd be turning only 2500rpm at that same speed with the tallest combination

|

Final Thoughts

Hopefully the above does a reasonable job of describing the paths to various horsepower levels you can achieve with your conversion. But we fully understand that

you may still have questions, so please don't hesitate to contact us at any time, we'll do our best to answer whatever questions you might have, and we'll roll

the information into the above to help others. We want to make this article as complete and accurate as possible.

Also, if you're interested in any of the above packages, we would be happy to put together a formal estimate for you and fire it off by email. It helps if you

fill out the form on the Contact Us page as it asks for all of the information we need to create a quote with shipping included.

Thanks in advance for your business with HAMMER PERFORMANCE, we sincerely appreciate it, and we look forward to working with you on your project.

|

|

|

|

|

|

|

Here's what we'll do:

Here's what we'll do:

Here's what we'll do:

Here's what we'll do: